If you had to choose the top KPIs you need to manage and improve your logistics performance, how many would you say there are? 10? 20? 100? There is no shortage of metrics available in supply chain, that’s for sure. But what are the top ones that can truly guide your management and decision-making?

Often, we find organizations focus on too many metrics to manage and monitor—many of which don’t support smart decision-making. By definition, a KPI is a quantifiable, measurable, and actionable metric that informs how the business is doing against critical success factors tied to business objectives and goals. Ultimately, KPIs lead to actions—KPIs that do not support you in making decisions are just metrics.

Featured Expert

Richard Cushing

Richard Cushing is a seasoned professional with a unique blend of experience and skills to help enterprises improve through re-engineered business processes and high-ROI demand-driven supply chain improvements.

Recommended Reading:

We asked Supply Chain Consultant Richard Cushing for his perspective on this topic. He had this to say, “Regardless of how efficient, reliable, and fit other data might be, if it is irrelevant for the decision timeframe, such data can only contribute to distraction and confusion. When irrelevant data is included with relevant data for the decision-makers, decisions are likely to be delayed, distorted, or—possibly—absolutely wrong for the present circumstances.

Therefore, my chief advice is to first determine the relevant data for decision-making. Then, be sure your systems are designed and developed to aid decision-making based only on the relevant data.”

Improve Service; Reduce Costs for Better Logistics Performance

As Albert Einstein said, “Not everything that counts can be counted, and not everything that can be counted counts.” If we focus on logistics, specifically, the most important KPIs boil down to two things: service and cost. Specific KPIs will differ between departments or areas of responsibility, but all should support improving service and reducing costs. Here we discuss the top four KPIs you need for better logistics performance.

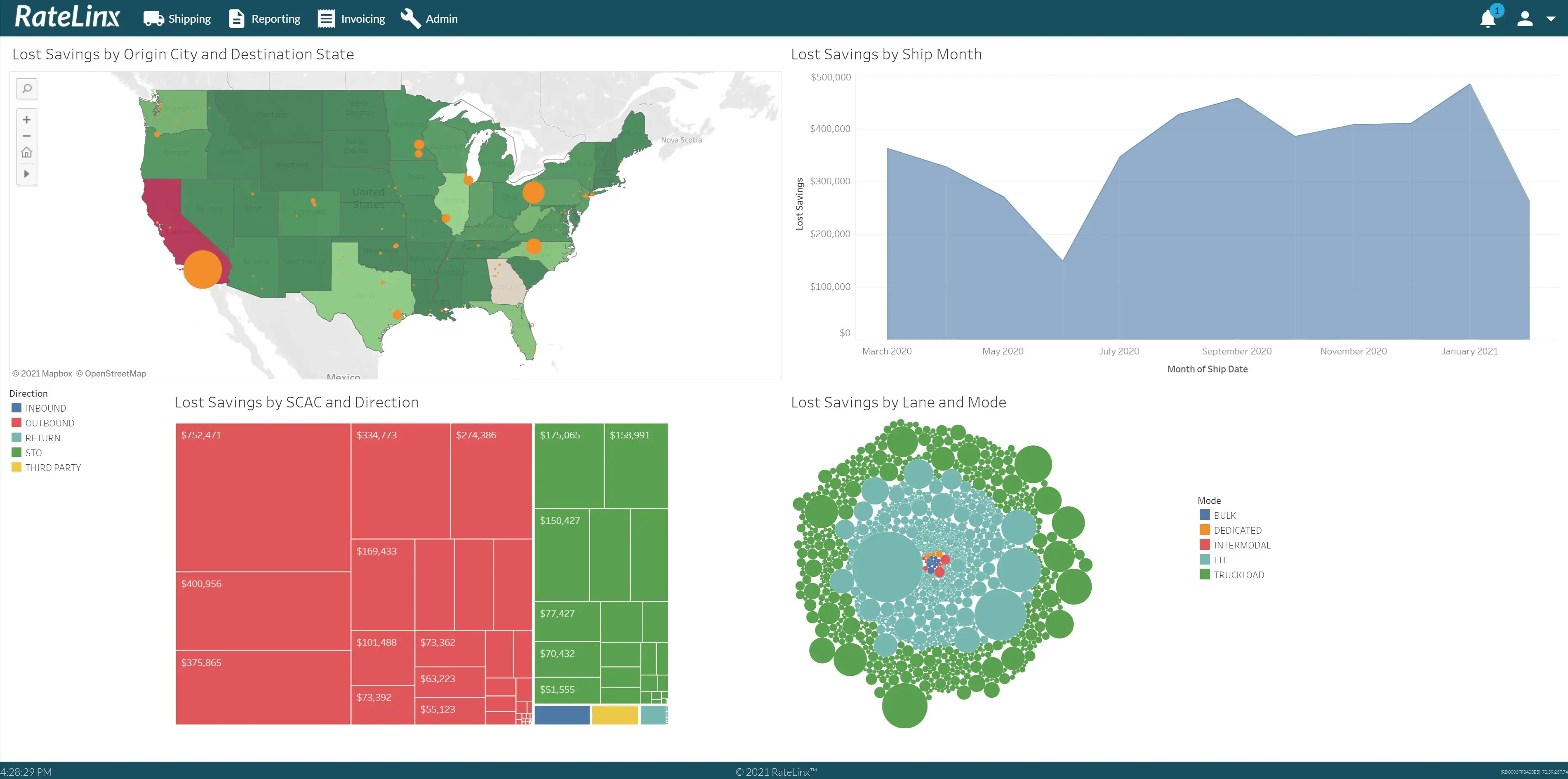

1. Lost Savings

The powerful, Lost Savings KPI measures and monitors transportation network compliance in real-time. It shows opportunities to reduce freight costs using more optimal carriers. While getting 100% business rule compliance on every shipment is not practical, knowing where cost-savings opportunities exist and taking action can make a big difference in monthly freight costs.

For logistics teams to leverage the Lost Savings KPI, real-time access to financial and logistics data is critical. And not just access, but having the software to integrate disparate data sources to achieve real-time insights.

Case Study: Fortune 500 Retailer Uncovers Big Cost Savings

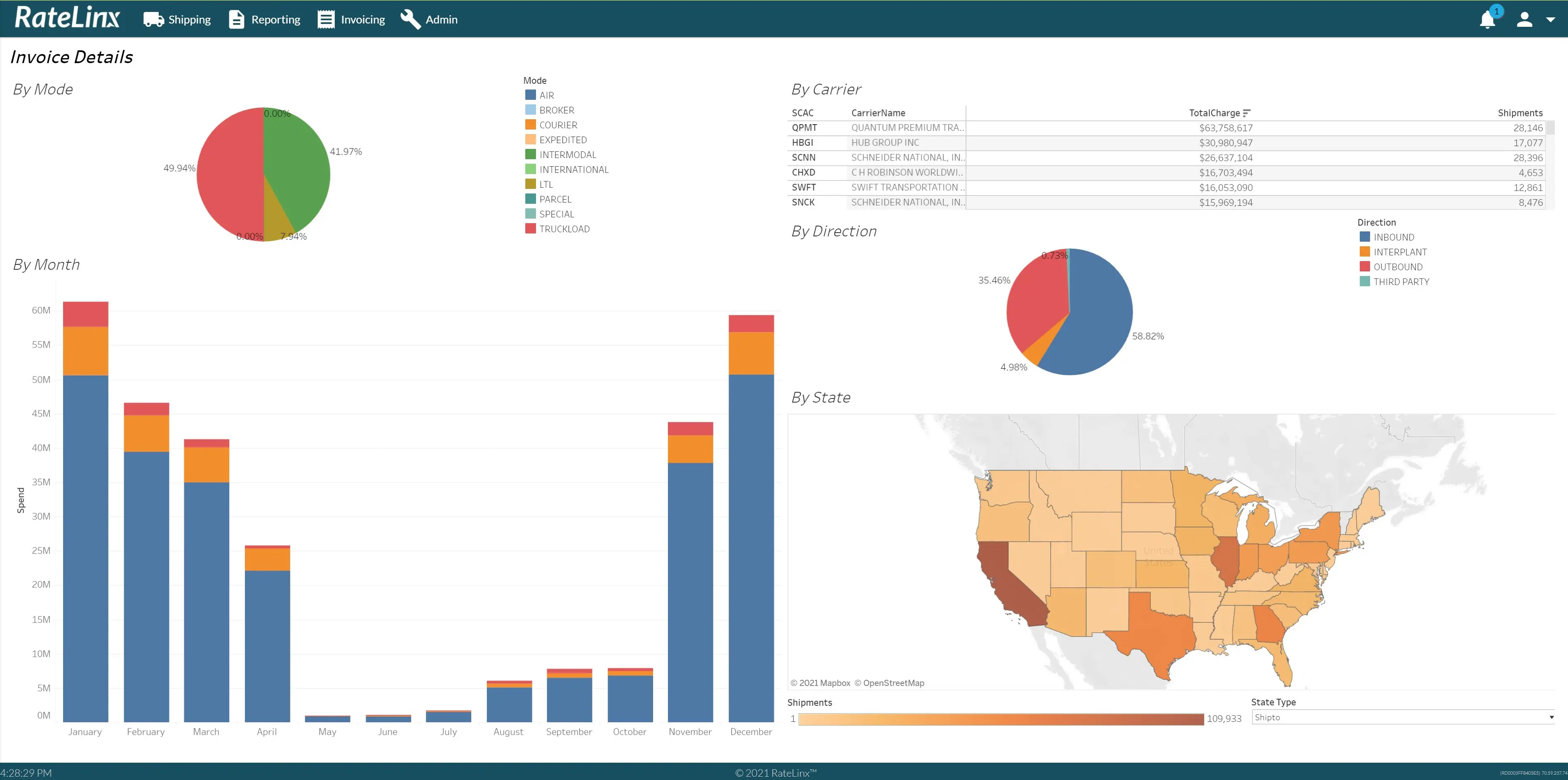

2. Freight Cost

On the surface, a freight cost KPI might seem obvious. But to glean actionable insights and make effective cost reduction decisions, the freight cost KPI must be contextually relevant, timely, and accurate. For example, the freight cost KPI should apply to the operations area. Depending on the company or structure, a transportation manager may want to see freight costs by mode, lane, and type. Procurement and inventory professionals may need visibility to freight cost by order, item, PO #, or as a % of Sales in order to impact logistics performance.

“When irrelevant data is included with relevant data for the decision-makers, decisions are likely to be delayed, distorted, or—possibly—absolutely wrong for the present circumstances.”

Just a lump-sum freight cost expense at the end of each month for the previous month might be enough for accounting to close the books. Still, it does not provide context for what happened so the logistics team can triage issues, solve problems, and make corrections for future shipments to improve logistics performance.

For example, a logistics manager who budgets to spend $3M in daily transportation shouldn’t have to wait until month-end to discover a $3.5M daily spend for the first nine days of the month. Having insights and real-time alerts to notify you costs are higher in recent days provide the opportunity to correct issues before costs get out of control.

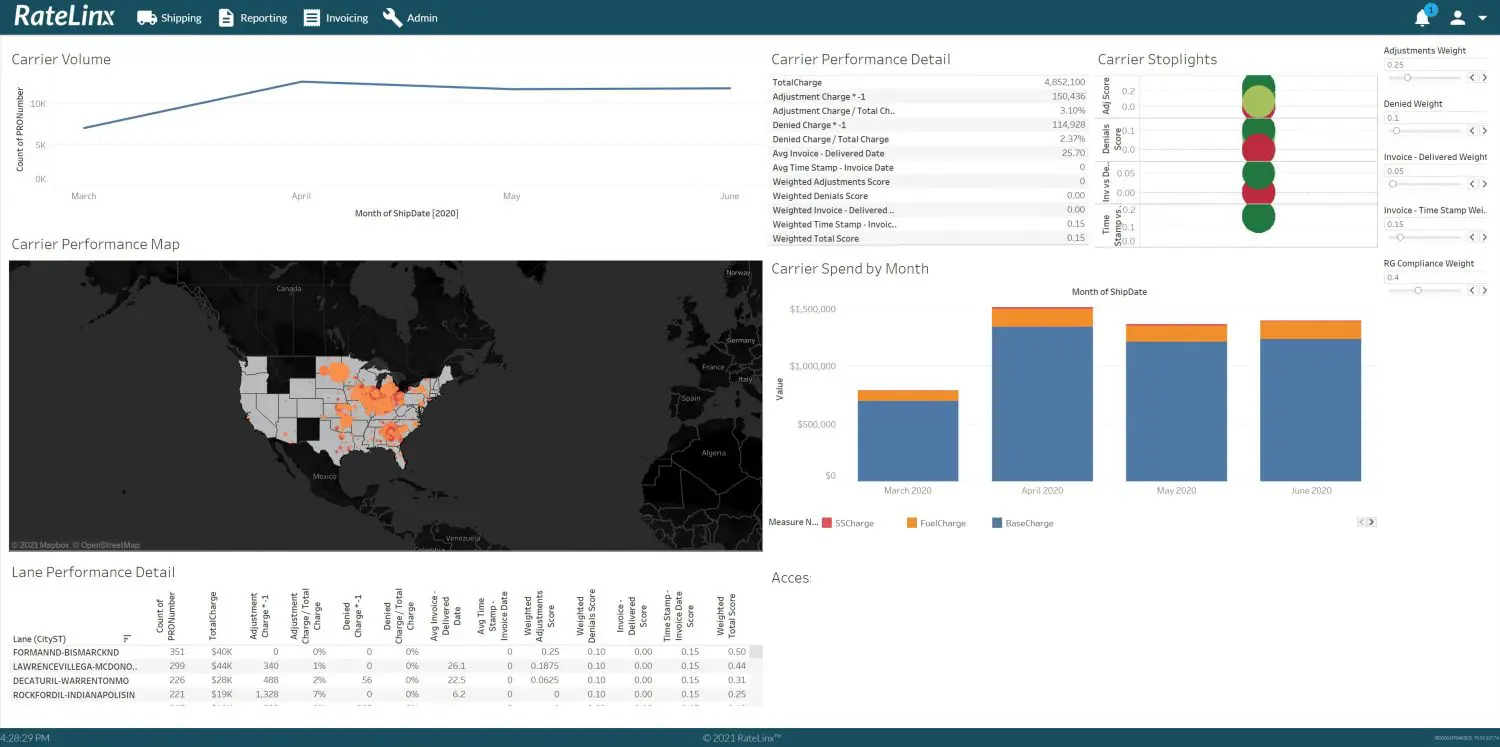

3. Carrier Selection & Scorecard

Carrier selection and scorecards impact both transportation and distribution or warehousing teams. Ultimately, they need to get their product from point A to point B on time and with no damages. For a delayed shipment that won’t arrive on time, the logistics team must know before it happens. If they don’t find out about the late shipment until the customer calls, there’s a service (and cost) problem. Furthermore, performance directly impacts freight costs and decisions regarding service level agreements or fulfilling customer expectations. It is crucial to keep accurate and timely reporting on carrier performance, ensuring carriers meet acceptance rates while delivering on-time-and-in-full.

We typically see the cost, quality, and logistics performance data needed is located across disparate systems and information silos. This diversity requires manual processes to acquire, process, or analyze the data. To be effective, carrier scorecard KPIs need to drill down to the carrier and lane level for truly accurate insights. Choosing the best suitable carrier is a balance between cost, quality, and performance. If the logistics team does not have visibility to all three, making good decisions around carrier selection will be impossible.

Like what you’re reading?

4. Supplier Scorecard

To truly improve customer service and reduce costs, inbound supplier performance is just as important to measure and monitor. Supplier relationships are critical to customer service. A supplier scorecard measures the quality, delivery, and responsiveness of suppliers. With this information, you can control your costs and compliance while allowing suppliers to leverage your best rates and utilize carriers in their preferred lanes. This information is essential in making purchasing decisions, as well as to distribution and warehouse managers.

Like freight cost, having a month-end report showing all the inbound shipments from the prior month does not provide the insights you need to inform your strategies. Using technology can bring detailed visibility and real-time reporting to inbound shipments, cost, quality, and punctuality of those suppliers. With Prescriptive InsightsSM, customized alerts that differentiate statistical outliers or variances outside the norm can be set up. These alerts can even be automated to deliver reliable results quickly.

The integrated data can quickly inform transportation teams of any issues that need attention to avoid additional fees or delays. For example, suppose an inbound supplier shipment is delayed due to bad weather. In that case, the distribution and warehouse teams can know right away to plan material flow and slot plans efficiently.

Start a Free 30 Day Analysis

Prescriptive InsightsSM Enable Proactive Decision-Making and Improved Logistics Performance

For a C-suite executive who needs to keep a pulse on what’s happening in the organization, it’s impossible to pay attention to everything happening in the supply chain. Seeing a month-end report from each department that shows results from 2 months prior is too late to investigate, plan, and solve increased costs, poor quality, or negative impacts on customer service.

For example, a mode shift is a common occurrence in organizations. Suppose the transportation manager expects a lane to be shipping via intermodal. Yet, someone in the plant shifts it to truckload, which costs more. The sooner the transportation manager realizes this shift, the sooner they can stop it and control extra costs. Prescriptive insights allow these types of alerts to occur in real-time.

“Having better data—meaning, more relevant data, and less irrelevant data—at the hands of an organization’s decision-makers means faster, more accurate, and more effective decisions. It should naturally lead to a higher return on investment. While many managers and executives are surprised to learn that more data does not necessarily mean better management, a faster and better return-on-investment should not be an entirely unexpected benefit.”

In the example of the late shipment, if the team receives an alert while the load is in transit, they can make an informed decision to contact the customer proactively or spend more to get it there on time. But without the insight alert, the shipment just runs its course, and no one knows when it will show up.

Accurate, Complete, and Timely Data

Data quality is accurate, complete, and timely, and contextually relevant data representing the real world. Without quality data, the KPIs, reports, predictive, and prescriptive actions are unreliable, inaccurate, incomplete, or ill-timed. Data quality makes actionable and prescriptive insights possible.

Richard Cushing cautions that more data does not necessarily mean better management. “Having better data—meaning, more relevant data, and less irrelevant data—at the hands of an organization’s decision-makers means faster, more accurate, and more effective decisions. It should naturally lead to a higher return on investment. While many managers and executives are surprised to learn that more data does not necessarily mean better management, a faster and better return-on-investment should not be an entirely unexpected benefit,” he says.

“After all, if relevant data leads to improved focus on relevant details essential for better decisions, and if better decisions are intended to improve profitability and cash flow, then the expected benefit should be an increasingly profitable supply chain and company.”

Typically a transportation professional spends tremendous time digging for data and making sense of it. Logistics data coming in from multiple, siloed systems make insights a challenge, if not impossible. By the time they get the information they need, it’s too late to take action. You can only achieve high-value and cross-functional insights once you have true data quality.

Quality Data = Improved Logistics Performance

While providers today understand the importance of data quality, very few execute and deliver true data quality to their customers. Without quality data, shippers will always struggle to meet their goals and deliver the operational efficiencies they need in their business. A data-quality, technology-driven logistics provider truly helps shippers confidently improve logistics performance, control spend, and stay ahead of changing conditions.

Supply Chain modernization and digital transformation is a steep challenge. Starting with the right data partner can accelerate the process and deliver back years in ROI and time-to-value.