2020 may have taken us all by surprise, but as we head into Q2 of 2021, we’re all a bit more prepared—right?

Right now, we’re dealing with increased border controls, complicated customs regulations, and reduced capacity for essential processes like long hauls and quick fulfillment. Between market surge and contraction, technology hurdles, remote workers, as well as shuttering businesses, our supply chain has been thrown several wrenches.

Here’s an account from a Ratelinx customer: “First we saw a steep drop in business. We also saw demand dramatically increase for specific materials used to respond to the COVID pandemic,” says Gaëtan Metra, Sr. Logistics Manager at Ecolab. “This means readjusting forecast, production, etc. There was significant time added to every process. We even had to change how we trained; moving much to virtual vs all in person with our delivery specialists.”

Luckily, according to some of our favorite experts in the supply chain industry, conditions for the future of supply chain are looking better — provided we’re properly prepared.

Here’s what they had to say when we posed them the following question:

How Should Supply Chain Experts Focus Their Attention This Year to Improve the Supply Chain?

“Last year, hardly anyone would have predicted that supply chain leaders would face this year’s particular slate of challenges. Given how volatile the world is right now, how should supply chain experts focus their attention this year?”

Featured Expert

Tamara McCleary

Tamara is a consultant focused on training businesses to prepare for digital transformation and the future of work, with a focus on human-machine partnerships, AI, robotics, IoT and blockchain. She also hosts the Tech Unknown podcast for SAP.

Recommended Reading:

Use Technology to Develop Agility

“If 2020 taught us anything it’s that technology plays a critical role in the supply chain. It also taught us how much we ALL rely on a functioning supply chain.

So the keyword for this year is agility. The supply chain must be agile, capable of pivoting on a dime, and coping with the unexpected. A healthy supply chain is the foundation of a functioning society.

Agility can only be achieved through technologies such as the IoT, and AI paired with machine learning. These technologies efficiently manage stock, inventory, and even increase workforce productivity, streamline supplier selection processes, and positively affect customer experience. Running efficiently on technology and automating processes is no longer a ‘nice to have’, it’s a ‘must-have’. And for the supply chain leader, this is no longer the ‘future plan’, it’s ‘now’.”

“The keyword for this year is ‘agility.’ The supply chain must be agile, capable of pivoting on a dime, and coping with the unexpected. A healthy supply chain is the foundation of a functioning society.”

Tamara McCleary, CEO, Thulium

Gaëtan Metra says that Ecolab is working to develop agility for the new normal: “We’re preparing for divisions to get back to volumes and ramping up for the new normal “post-COVID,” but in the meantime, we’re strategizing how we may work differently and incorporate different delivery strategies,” he says.

Nate Endicott, Senior VP of Global Sales, Marketing, and Partnerships for RateLinx adds, “An important part of being an agile supply chain, is being data-driven. Most global manufacturers and top retailers are 100% focused on gaining a competitive advantage by leveraging data. However, the data has to be accurate, complete, and timely to effectively contribute to an agile supply chain.”

Featured Expert

Daniel Stanton

Daniel “Mr. Supply Chain” Stanton is dedicated to educating and elevating supply chain leaders. He’s a LinkedIn Learning Instructor and the author of Supply Chain Management for Dummies.

Recommended Reading:

Invest More in Automation

“We are going to see a huge investment in automation by companies across the entire supply chain. Over the last year, we saw a major payback for companies that had been early adopters of automation technologies. Once COVID-19 hit, companies that had digital solutions in place were able to respond to marketplace changes more quickly.

As a result, customer expectations for these options are much higher today. While making investments in technology can be a smart move, we need to be thoughtful about the solutions we choose and the order in which they are deployed. My suggestion is that companies should have a strategic roadmap, rather than making ad hoc decisions about where to automate. Think in terms of the three flows in a supply chain – money, materials, and information – and look for opportunities to improve planning, execution, and visibility throughout.”

“Think in terms of the three flows in a supply chain-money, materials and information-and look for opportunities to improve planning, execution & visibility.”

Daniel Stanton, Founder and CEO, Mr. Supply Chain

Featured Expert

Greg White

Greg White has a storied career in supply chain and currently serves as the Principle and Host at Supply Chain Now in addition to his role at Trefoil Advisory. He preaches the importance of balancing inventory with customer demand and solutions that expedite fulfillment.

Recommended Reading:

Like what you’re reading?

Keep the Focus on Customer Service

“Currently, supply chain professionals must adopt the perspective that the supply chain is first a customer experience exercise. The primary goal is to get goods to the customer while mitigating anything that creates risk regarding:

- Customer experience – fulfillment, cost, quality, etc.

- Economics – revenue, efficient operations, market structures & business models, production & inventory cost

- ESG or Environmental, Social and Governance (therefore corporate identity) – ethical sourcing, sustainability, fair-trade & human rights

- Disruptors – complexity, distance, technology, security (cyber & physical), weather, infrastructure, etc.

- And more, of course…

When we start first with customer experience goals in mind and acknowledge risk management as paramount in meeting that end, appropriate goals, models, actions, and results follow.”

“Supply chain professionals must adopt the perspective that the supply chain is first a customer experience exercise.”

Greg White, Advisor, Principal, Host, Supply Chain Now

Nate Endicott also weighed in on this topic: “On the customer service side, I suggest looking at improvements in three areas—cash, cost, and service. Consider how the customer experience will be impacted by making improvements and strategy shifts.”

Featured Expert

Beth Morgan

One of the most prolific female voices among supply chain and logistics leaders, Beth is committed to the advancement and acceleration of the role and careers of women in supply chain. She’s also a foremost authority on supply chain research and analysis.

Recommended Reading:

Balance Long and Short-Term Strategies

“Good supply chain management has always been about balancing long-term strategy with short-term demands. Although the events of 2020 put pressure on supply chains in ways we never could have expected, successful supply chain leaders can keep their hands steady on the tiller throughout periods of change and economic and political uncertainty, thereby ensuring that supply chains remain as resilient as possible for the long term.

“Good supply chain management has always been about balancing long-term strategy with short-term demands.”

Beth Morgan, Founder & CEO, BOOM!

We’ve seen many examples of this over the past year as businesses placed urgent focus on the needs generated by the pandemic at the same time as keeping an eye on the bigger picture, with ongoing investment in areas such as environmental sustainability and corporate social responsibility, digital innovation and investment in organizational talent-focused initiatives. The ability to maintain this balance will remain critical as we navigate the coming year and beyond.”

You may also be interested in…

Nate Endicott at RateLinx had this to add, “In order to not be reactive to pandemics or other challenges that have happened this past year, you have to build your supply chain strategies on quality data in order to be resilient. If you have good, quality data, not only can you react quicker, but you can be proactive in your decisions and still hit your year-over-year improvements.”

Featured Expert

Scott W. Luton

With Supply Chain Now, Scott Luton has created a dedicated resource for supply chain leaders to optimize the present and plan for the future. The company publishes a regular interview podcast, as well as webinars and blog posts about all things supply chain.

Recommended Reading:

Lead through Communication & Team Work

“We are seeing supply chain leaders successfully navigate the current volatile and uniquely-challenging environment, amongst other things by:

- Improving communication and market intel exchange with their upstream and downstream supply chain partners, and gathering critical insights on enterprise risk;

- Becoming more serious about investing in their talent acquisition, development, and management strategy;

- Aligning the segments of the enterprise to be able to tackle the appropriate & ‘best fit’ digital transformation approach;

- Leadership teams becoming very frank and honest about what ‘smart business’ is and how it is defined. This can lead to more investment in the right business – and the outsourcing, selling off, or outright elimination of the wrong business. The times call for a laser-focus on what works, meeting consumer demand, and deepening consumer relationships, in a way unmatched in recent memory (if at all);

- Embracing these historically challenging times as the ultimate challenge to accept strategic continuous improvement & business transformation”

“The times call for a laser-focus on what works, meeting consumer demand and deepening consumer relationships in a way unmatched in recent memory.”

Scott Luton, Founder, CEO & Host, Supply Chain Now

Keeping employees informed and keeping morale up is a priority for Ecolab, too. Says Gaëtan, “It’s crucial to recognize people for the work done and celebrate your staff for accomplishments to ensure engagement.”

Featured Expert

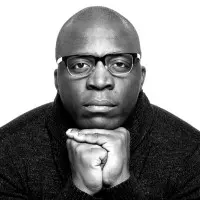

Adebayo Adeleke

Adebayo is a retired U.S. Army Officer, supply chain enthusiast, businessman and social entrepreneur. His military career is broadly defined by exposure to some of the world’s most stringent supply chain practices. Today, Adebayo spends his time as a Managing Partner at Pantote Solutions LLC in Dallas, TX, and is also the President and CEO of Adebayo Adeleke LLC, a Principal Partner and Senior Supply Chain Consultant for Epot Consulting Limited. He’s also a lecturer in supply chain management at Sam Houston State University.

Recommended Reading:

Develop Your Risk Management Systems

“I foresee a global supply chain slowly recovering from the impact of COVID-19. I believe we now will slowly start to shift back to pre-pandemic norms while simultaneously accelerating forward into the post-pandemic future. I also foresee industries reevaluating their supply chain strategy and improving their supply chain risk management framework. I foresee organizations cautiously optimistic about their global supply chain framework, baring the impact of geopolitical events.

I advise supply chain experts to focus their effort on developing their supply chain risk management system and to be progressive in their thinking by redefining their supply chains using circularity concepts, as well as using different technology ecosystems to enhance their supply chain viability.”

“I advise supply chain experts to focus their effort on developing their supply chain risk management system and to be progressive in their thinking.”

Adebayo Adeleke, Managing Partner, Pantote Solutions LLC

Start a risk-free, no-IT analysis with RateLinx

Featured Expert

Rosemary Coates

Rosemary is a Global Supply Chain, Procurement, and Manufacturing Expert focusing on Chinese sourcing and manufacturing, and logistics with 30 years of experience in industry, consulting and expert witnessing. An author of 5 supply chain books, including an Amazon.com best seller, she has consulted with 80 countries around the world and across a diversity of industries.

Recommended Reading:

Invest More in Sustainability & Infrastructure

“With a transition of political power coming up, I would anticipate some changes and shifts in priority such as:

- Return to more normal and traditional politics and U.S. foreign policy – calmer global supply chains with fewer political disruptions;

- Reinstitute environmental policy; focus on green energy industries in America;

- Development of a National Industrial Policy, including critical industries such as pharmaceuticals, medical equipment, high tech, rare earth elements;

- Federal aid and tax breaks for industrial development in America;

- Investment in rebuilding the American infrastructure – highways, bridges, and ports in need of repair;

- Continuation of tariffs on China – they are popular with the public and across party lines. However, the tariff rates are likely to be lowered”

“Expect a return to more normal and traditional U.S. foreign policy – calmer global supply chains with fewer political disruptors.”

Rosemary Coates, President, Blue Silk Consulting

Gaëtan agrees that sustainability will be a major focus this year and beyond, as part of a broader push for more transparency and accountability: “Data analysis as a priority in the supply chain is an emerging trend in 2021,” he says, “along with going green, and getting better transparency and visibility throughout the supply chain.”

Supply Chain Needs to Be Tech-First & Flexible

If the supply chain is to improve this year, agility must take center stage. Supply chain leaders must focus on developing the ability to adapt, and keep things moving, despite whatever challenges arise.

This type of flexibility can only be achieved through a swift adoption of technologies like loT, AI, and machine learning. Together, these technologies can manage stock and inventory, increase productivity, and streamline supplier processes.

“Flexibility can only be achieved through quality data. Before supply chains can be tech-first and flexible, they must take a data-first approach. Now, more than ever, shippers are wanting to digitize their decision-making and ensure their year-over-year initiatives achieve the results they’re expected to. Before deploying technology, I recommend shippers first diagnose possible unintended consequences to the business. By identifying the real issue, effective strategies and solutions can be put into place to ensure initiatives are reliable. Having a data-first approach is an important first step. Taking this a step further to leverage prescriptive insights gives shippers the competitive advantage they desperately need,” adds Nate Endicott of RateLinx.

Keep your logistics priorities current by reviewing our top findings from the 2020 Ratelinx Survey on Logistics Technology and Visibility.